EcoIn HVAC system special glass wool

EcoIn HVAC System is a glass wool product insulation and noise reduction system. The system uses the uniform slender high performance glass fiber, through the environmental protection formula binder curing molding, and a variety of high performance veneer and surface treatment, processing products.

These products are widely used in various parts of HVAC system that need insulation and noise reduction, including HVAC system special glass wool board, glass wool felt, glass wool duct lining and glass wool tube shell. The characteristics and advantages of these products not only lie in the high performance of their materials, but also in their excellent thermal insulation and sound absorption performance, overall non-combustible thermal insulation materials, durable and stable performance and the green concept of environmental protection building materials.

The unique features and advantages of EcoIn HVAC system lie in many aspects.

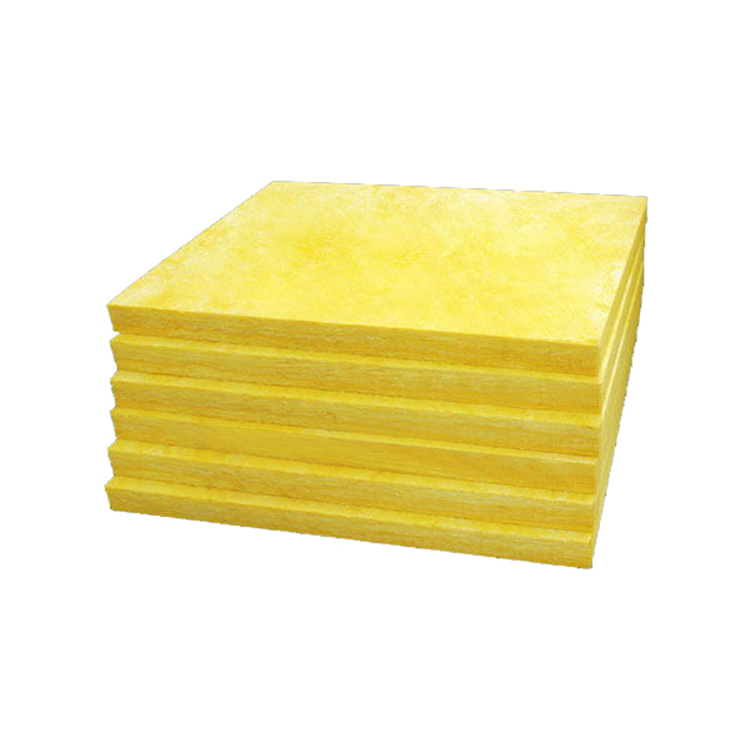

- Hvac system special glass wool board

The first is the hard plate HVAC system special glass wool board, the outer surface of the high strength moisture-proof veneer, can be applied to the rectangular metal air duct and surface equipment of the outer surface heat insulation, especially suitable for the occasion of the requirement of beautiful surface. The product is easy to install and smooth and crisp in appearance.

| Performance | Test Method | Technical Requirements |

| Operating Temperature | ASTM C411 | -18℃ ~ 232℃ |

| Hot Load Shrinkage Temperature | GB/T 13350 | Meets requirements |

| Mass Moisture Absorption | ASTM C1104 or GB/T 5480 | ≤ 5% |

| Corrosivity | GB/T 17393 | Meets requirements |

| Fungal Resistance | ASTM C1338 | Meets requirements |

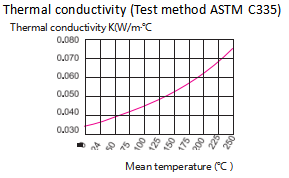

| Density (kg/m3)

Thermal Conductivity (W/m• K) @25℃ |

GB/T 5480 GB/T 10294 | 32 40 48 64

0.034 0.033 0.033 0.032 |

| Combustion Performance | ASTM E84 | Flame Spread: 25, Smoke Developed: 50 |

| BS 476 | Class 0 | |

| GB 8624 | Class A non-combustible material |

| Thickness(mm) | Density (kg/m3) | 32 | 40 | 48 | 64 |

| 25 | 0.76 | 0.76 | 0.78 | ||

| 30 | 0.88 | 0.91 | 0.91 | 0.94 | |

| 40 | 1.18 | 1.21 | 1.21 | 1.25 | |

| 50 | 1.47 | 1.52 | 1.52 | 1.56 | |

*R-Value = thickness / thermal conductivity (unit: m2·℃/W)

| Density(kg/m3) | 32 40 48 56 64 80 96 |

| Thickness(mm) | 25 30 40 50 |

| Width (mm) | 600 |

| Length (mm) | 1200 |

- Glass wool felt for HVAC system

The second is the rolled felt-like glass wool felt for HVAC system, its external surface is also made of high strength moisture-proof veneer. The product can be used for insulation of various shapes of air ducts and equipment external surface, its fiber is soft, comfortable, flexible application, close fitting, installation gap less, high insulation efficiency.

| Performance | Test Method | Technical Requirements |

| Operating Temperature | ASTM C411 | 4℃ ~ 121℃ |

| Hot Load Shrinkage Temperature | GB/T 13350 | Meets requirements |

| Mass Moisture Absorption | ASTM C1104 or GB/T 5480 | ≤ 5% |

| Corrosivity | GB/T 17393 | Meets requirements |

| Fungal Resistance | ASTM C1338 | Meets requirements |

| Density (kg/m3)

Thermal Conductivity (W/m• K) @25℃ |

GB/T 5480

GB/T 10294 |

32 40 48 64

0.034 0.033 0.033 0.032 |

| Combustion Performance | ASTM E84 | Flame Spread: 25, Smoke Developed: 50 |

| BS 476 | Class 0 | |

| GB 8624 | Class A non-combustible material |

| Thickness(mm) | Density (kg/m3) | 24 | 32 | 40 | 48 |

| 25 | 0.69 | 0.74 | 0.76 | 0.76 | |

| 30 | 0.83 | 0.88 | 0.91 | 0.91 | |

| 40 | 1.11 | 1.18 | 1.21 | 1.21 | |

| 50 | 1.39 | 1.47 | 1.52 | 1.52 | |

*R-Value = thickness / thermal conductivity (unit: m2·℃/W

Standard specifications:

| Density(kg/m3) | 24 32 40 48 |

| Thickness(mm) | 25 30 40 50 |

| Width (mm) | 1200 |

| Length (mm) | 10000-30000

( It is determined by volume weight and thickness) |

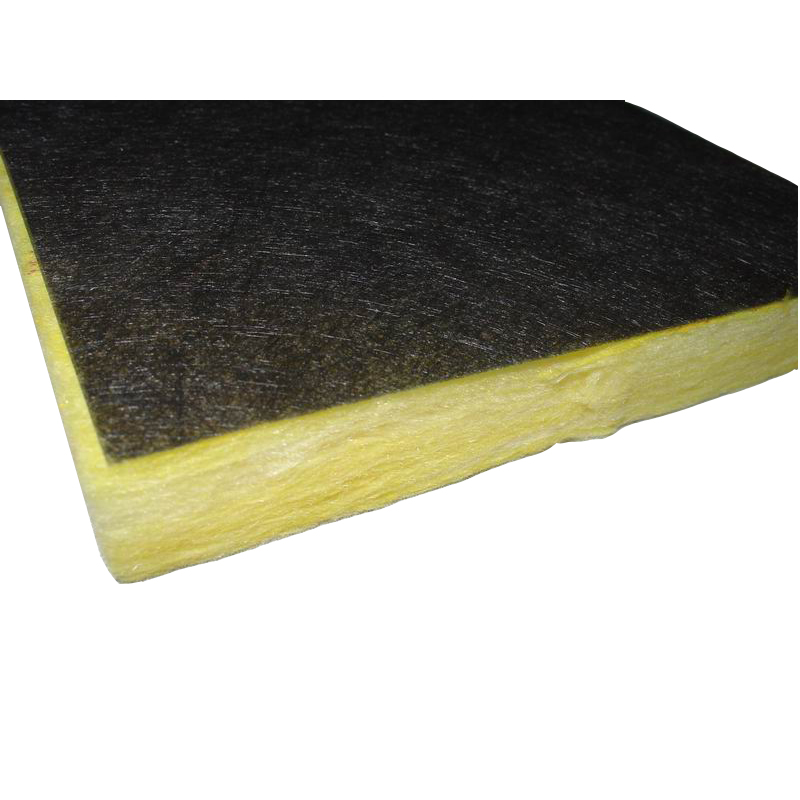

- Glass wool duct lining for HVAC system

The third product is the HVAC system special glass wool duct lining, the surface of the original factory online composite a layer of strength wear-resistant enhanced black BGT veneer. The product is installed in the air duct and equipment, and direct contact with the return air flow, heat preservation and noise reduction, is the best choice for occasions with high acoustic requirements. Its friction-resistant BGT surface can be washed by airflow for a long time, and the product provides excellent sound absorption and noise reduction performance while heat insulation.

| Performance | Test Method | Technical Requirements |

| Operating Temperature | ASTM C411 | < 121℃ in air ducts |

| Hot Load Shrinkage Temperature | GB/T 13350 | Meets requirements |

| Maximum Air Velocity | UL 181 | 20.3 m/s |

| Moisture Absorption | ASTM C1104 or GB/T 5480 | ≤ 5% |

| Corrosiveness | GB/T 17393 | Meets requirements |

| Mold Resistance | ASTM C1338 | Meets requirements |

| Density (kg/m3)

Thermal Conductivity (W/m• K) @25℃ |

GB/T 5480

GB/T 10294 |

32 40 48 64

0.034 0.033 0.033 0.032 |

| Combustion Performance | ASTM E84 | Flame Spread: 25, Smoke Developed: 50 |

| Thickness(mm) | Density (kg/m3) | 32 | 40 | 48 | 64 |

| 25 | 0.76 | 0.76 | 0.76 | 0.78 | |

| 30 | 0.88 | 0.91 | 0.91 | 0.94 | |

| 40 | 1.18 | 1.21 | 1.21 | 1.25 | |

| 50 | 1.47 | 1.52 | 1.52 | 1.56 | |

*R-Value = thickness / thermal conductivity (unit: m2·℃/W)Standard specifications:

| Density(kg/m3) | 24 32 48 64 |

| Thickness(mm) | 25 30 40 50 |

| Width (mm) | 600 |

| Length (mm) | 1200 |

- Hvac system special glass wool tube shell

Finally, the glass wool tube shell for HVAC system is a circular tube shaped product made of glass wool rolled and shaped by raw cotton. The outer surface is online composite high strength moisture-proof veneer. The product is suitable for all kinds of cold and hot water pipe external insulation. Its shape circumference, uniform thickness distribution, insulation effect is good, at the same time to provide supporting moisture resistance accessories and end face treatment measures, to adapt to various occasions of insulation moisture-proof requirements, to ensure that the insulation system for a long time and reliable operation.

| Performance | Test Method | Technical Requirements |

| Operating Temperature | ASTM C411 | -18℃ ~ 232℃ |

| Hot Load Shrinkage Temperature | GB/T 13350 | Meets requirements |

| Mass Moisture Absorption | ASTM C1104 or GB/T 5480 | ≤ 5% |

| Corrosivity | GB/T 17393 | Meets requirements |

| Fungal Resistance | ASTM C1338 | Meets requirements |

| Density (kg/m3)

Thermal Conductivity (W/m• K) @25℃ |

GB/T 5480

GB/T 10294 |

32 40 48 64

0.034 0.033 0.033 0.032 |

| Combustion Performance | ASTM E84 | Flame Spread: 25, Smoke Developed: 50 |

| BS 476 | Class 0 | |

| GB 8624 | Class A non-combustible material |

| Density (kg/m3) | 64 80 100 |

| Thickness (mm) | 25 30 40 50 60 65 70 |

| Length (mm) | 1000 1200 |

| Pipe diameter (mm) | 16 ~ 457 |